OPTIONS

SERIES

XD Series

Unleash the power with our XD Xtreme Duty Series! Engineered for durability and performance, this processor is built for those who demand nothing but the best. This series features the following upgrades:

- 19 mm / 3/4" Auger Flighting

- 5 mm / .2" Tub Wall and Floor 3CR12 Stainless Steel Liners

- Heavy Duty Forage Cutting Blades

- Auger Magnets

- XD Aggressive Styling

Available on 900T and larger models.

AUGERS

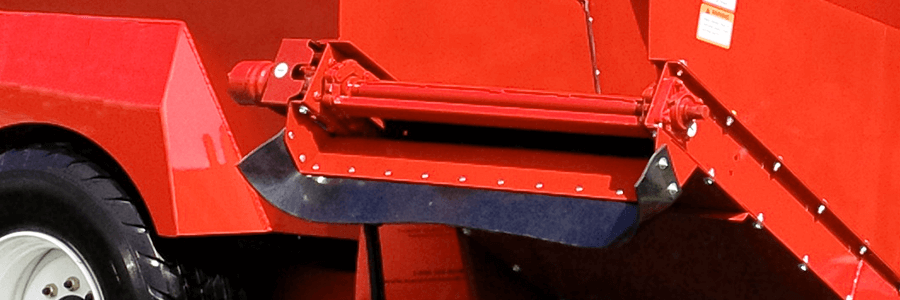

Cutting Auger

Our standard patended feed cutting auger, complimented with serrated knives, backing plates and fasteners. Fast and accurate processing and blending of all feed commodities. A taller auger than our corn auger, featuring an additional row of flighting at a shallower pitch.

Corn Auger

Comes standard without knives, but with piercings for the option of adding them. Designed to be a gentle and effective auger for the purpose of flaked corn feeding, with wider flighting and a steeper pitch than our cutting augers. Designed to eliminate fines while producing a fast and accurate mix. It equals or surpasses the performance of a horizontal mixer and increases the capacity considerably - the reason being that our auger speed turns at 32 rpm compared to the horizontal mixer auger speed of 18 – 20 rpm. Other vertical auger manufacturers cannot handle flaked corn without causing damage to the corn.

Hard Facing

Available either on the augers, or as a package on the augers, doors, and baffles. We use Chromium-Niobium alloy designed to resist severe abrasive wear - other manufacturers use standard welding wire. A great way to maximize the life of the high wear points at minimal cost.

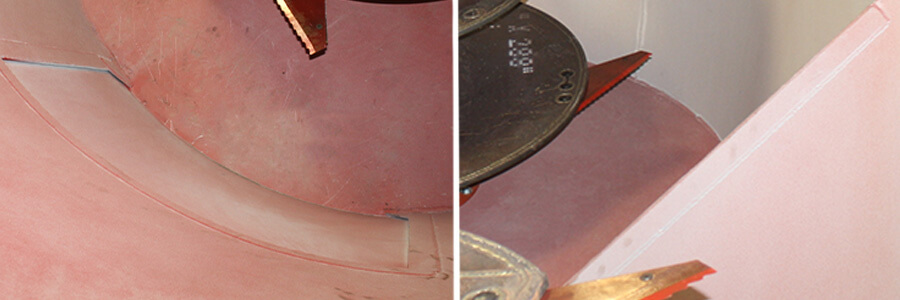

Liners

Designed to protect against wear and abrasion and available in 12GA 304 Stainless Steel. Welded directly onto the auger flighting, it is the ultimate life extender for an auger.

Extended Backing Plate

In certain applications the addition of extended backing plates can improve the performance of the feed processor. Keep in mind that adding extended backing plates will cause an increase in horsepower requirements. Never place an extended backing plate on the very top knife position of an auger.

Sweep Arms

For twin and triple models with side doors to aid with feed discharge.

CONVEYORS

Extended Dogleg Conveyor

This provides an additional 17” extension to the standard dogleg conveyor.

Hydraulic Folding Conveyor

Allows the operator to maneuver the machine in tighter areas with the conveyor upright, reducing the overall width of the machine until the conveyor is lowered to discharge the ration. Available with 42” or 54” folding options.

Dual Discharge Conveyors

For the producer who needs to feed out on either side of the mixer. 8’ conveyors require a swing gate for Dual Discharge.

Swing Gate

Allows for dual discharge feeding on 8’ conveyors. The swing gate prevents feed from spilling off the conveyor without an end shield.

Hydraulic Extender

Allows operator to extend and contract the conveyor from inside the tractor cab without stopping to adjust position.

Side Door Conveyor

On single auger units, 21” Fixed and 36”, 44”, 72”, and 96” Hydraulic Fold-Up conveyor configurations are available for heightened feed discharge.

Bolt-On Magnet Kit

Can be placed anywhere on conveyor shields to remove ferrous material and minimize hardware poisoning in the feed as it passes by.

CHUTES

Fixed Drop Chute

Designed to provide more accurate placement of your feed, this drop chute is easily bolted onto the unloading conveyor.

Magnetic Drop Chute

Magnetic Drop Chutes give producers peace of mind, removing ferrous material and minimizing hardware poisoning in the feed as it passes by.

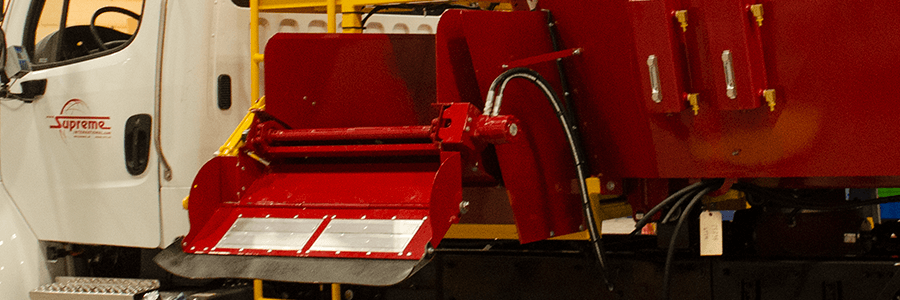

Hydraulic Folding Dropchute (pictured with Magnets)

Designed to provide more accurate placement of your feed, the folding option allows adjustment of the discharge angle and for the chute to be pivoted up to help with clearance.

TUB

10” Industrial Belting Extension

The industry’s most durable HD 1/2” belting incorporating a double reinforcing layer along both sides of the tub, for more rigidity to prevent collapse during loading. This industrial strength belting will control spillage when processing rations with a high percentage of roughage.

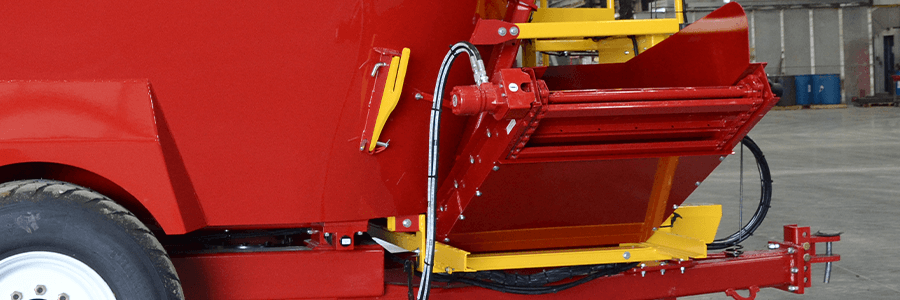

Commodity Door

This convenient door includes a fixed chute and is designed for quick and easy unloading of batch commodities. Available on most Supreme processors.

Side Doors (chutes pictured with Magnets)

Various side door configurations are available on single auger models, as well on twin models 900T and up to triple models.

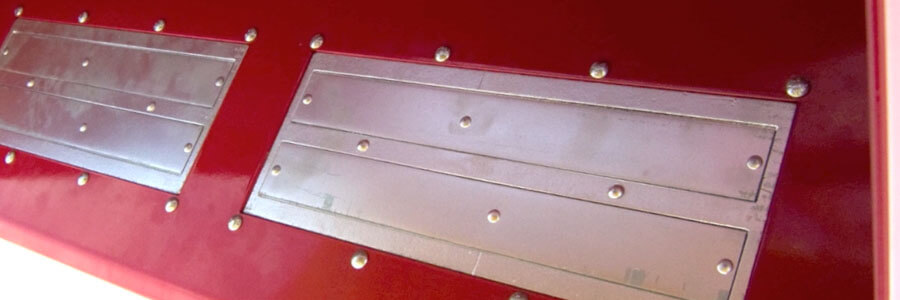

Floor and Wall Liners

Provides protection against tub wear and abrasion where you need it most. These liners are available in AR200 or 12GA 302 Stainless Steel and are welded directly to the interior wall of the tub and/or floor.

Hard Facing

Available either on the augers, or as a package on the augers, doors, and baffles. A great way to maximize the life of the high wear points at minimal cost.

PULL-TYPES

Constant Velocity PTO

The optional Weasler Constant Velocity PTO is designed with their patented ball and socket design and lubrication system, as well as, Weasler’s patented articulated guard system for maintaining full coverage up to 80 degree angles. Custom engineered for Supreme.

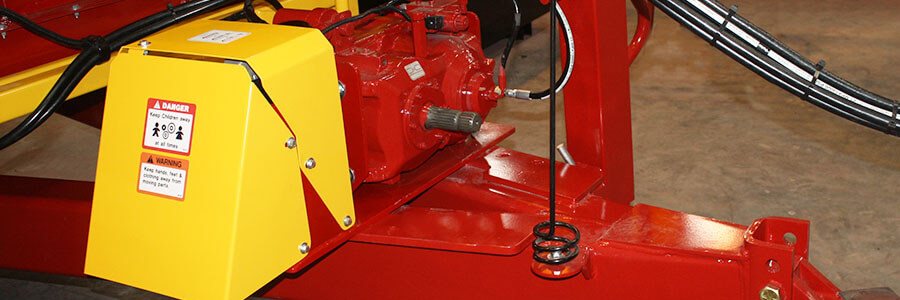

Two-Speed Gearbox

For lower horsepower tractors, a two speed gearbox is available which lowers the machine’s horsepower requirements by 20%, and provides additional power when required for tougher materials. Standard hydraulic shift with manual override. Available on most pull-type models.

Autoshift Two-Speed Transmission

Zuidberg is an industry leader in HD transmission applications, and makes significant strain reduction on large, heavy loads. It automatically downshifts to reduce load on the tractor, and automatically upshifts to maximize mixing efficiency. Available on most larger pull-type models.

Hitches

PPI-301, PP40XL, Small Supreme, Large Supreme, 3-Bolt Supreme and Articulating hitches are available. Options vary for each pull-type model.

Hydraulic Jack

The Hydraulic Jack can lift any pull-type processor quickly and efficiently.

Flotation Tires

Upgrade to a flotation tire and wheel package and you will be ready for varying types of terrain conditions from rough to soft and muddy.

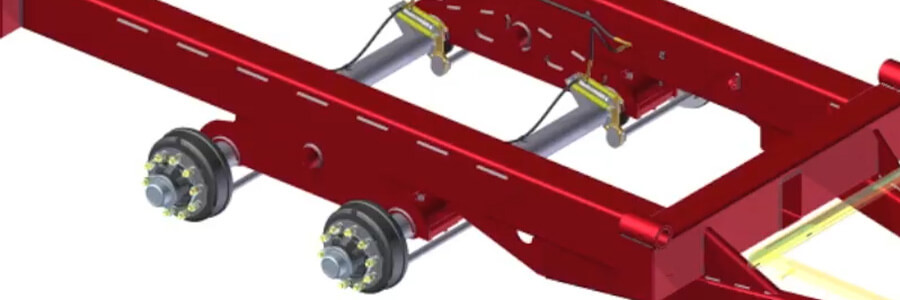

Tandem Axle Walking Beam

Designed to distribute and carry the weight of the mixer through the tandem axle easily and effectively. Available on 900T to 1700TR.

Hydraulic Braking Axles

Available in hydraulic/hydraulic and electric/hydraulic to assist with mixer stability on slopes and rough terrain.

Taillights

Available on all pull-type models. Style dependent on frame size.

TRUCK MOUNTS

FEPTO Drive

The Front Engine PTO drive (FEPTO) on hydrostatic or hybrid truck mounts allows for lower truck costs and improved access to the drive system for easy maintenance.

REPTO Drive

Rear Engine PTO Drive (REPTO), available on some hydrostatic truck mount models. Provides users with a shorter overall truck length, while protecting the hydraulic drive system behind the cab of the truck.

Super Sweep 2 Speed Drive

An option for hydrostatic truck mounts that allows high RPM clean out for the final 1,500 lbs / 680 kg of the ration.

DELIVERY BOX

End Dump

This option gives the ability to open the rear door and reverse the floor chain, offering users the ability to deliver commodity batches quickly and effectively. This end dump features a hydraulic tensioning system and simple hydraulic lift cylinders that make using the end door safe and easy.

SCALES

Dinamica Generale Main Scales

Including: DGStad02, DG500, DG600 and DG8000-IC

Dinamica Generale Accessories

Including: Extra Display, DTM IC Cloud Software, Dina TEL 3 Kit, Sound Alarm and Printer

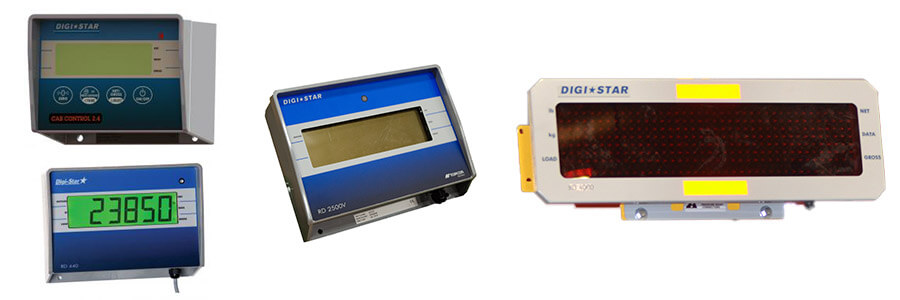

Digi-Star Main Scales

including: EZ400, EZ2500V, EZ2810, TMR3600, EZ3600 and EZ4600

Digi-Star Accessories

Including: Cab Control 400, RD400, RD2500V, RD4000, Zeroer, Sound Alarm, ERM WiFi and TMR Tracker software suites

HYDRAULICS

Selector Valves

Manual and electric function valves allow an operator to split a tractor’s existing circuit to accommodate more hydraulic functions. Available in 2 function manual, and 2, 3, and 4 function electric.