More Powerful Cutting. More Thorough Mixing.

More Accurate TMR Management.

Your All-In-One Solution For Proper TMR Management

A Supreme Feed Processor is your all-in-one material processing solution for proper TMR management. First, it is a powerful feed cutter that allows you to accurately process all types of roughage into uniform lengths of 1” to 6”. Next, it is a thorough feed mixer that blends your feed and feed additives into a single, uniform ration without grinding or damaging the feed. Finally, it is an efficient feeder that allows you to discharge ration in even, measured amounts for unparalleled control of your feeding operations.

Reduce Your Down Time

And Repair Costs

Supreme Feed Processors feature simple, professionally engineered designs, minimal moving parts and premium quality components. That means more durable, longer lasting machines that deliver reduced downtime and fewer maintenance related costs down the road.

Achieve A Higher Quality Feed

Not only do Supreme Feed Processors cut material uniformly, they cut it cleanly, so you don’t lose food value due to shattered stems and leaves. What’s more, the mixing action is gentle and accurate so that feed and additives are thoroughly blended, not ground together. The result is a more uniform, more palatable, healthier feed mixture that your animals won’t separate.

Reduce Your Total Capital

Investment Cost

Because a Supreme Feed Processor cuts and mixes your feed all in one machine, it eliminates the need for additional processing equipment, thus reducing your total capital investment cost. Supreme’s extremely efficient auger design requires far less horsepower to accomplish the same work as comparable mixers, which translates into reduced fuel costs.

Reduce Your Processing Time

Up To 50%

Every Supreme comes standard equipped with the Supreme Patented Auger design. Employing 4 separate Auger patents, the Supreme will cut and mix material simultaneously and can reduce your daily workload by up to 50% over most other vertical mixers, while still delivering the most accurate and thoroughly mixed ration in the industry. Over the course of a year, these speed and accuracy advantages will translate into substantial savings in time, labor, fuel, and feed costs, providing a handsome return on your investment.

Cut And Process Your Most

Difficult Materials

Every Supreme comes standard equipped with the Supreme Patented Auger design. Employing 4 separate Auger patents, the Supreme will cut and mix material simultaneously and can reduce your daily workload by up to 50% over most other vertical mixers, while still delivering the most accurate and thoroughly mixed ration in the industry. Over the course of a year, these speed and accuracy advantages will translate into substantial savings in time, labor, fuel, and feed costs, providing a handsome return on your investment.

Feed Mixers V.S. Feed Processors

One of the most common questions in the field is “What is the difference between a vertical processor and a horizontal mixer?” One is simply a feed mixer, while the other is a feed processor. Horizontal mixers require pre-processed commodities, and then proceed to blend a TMR ration. Vertical processors are capable of processing commodities such as whole forage or silage bales to the desired length of the producer. Another key difference is the amount of moving parts on a horizontal feed box vs. a vertical processor. Instead of chains and sprockets to drive multiple reels and paddles, verticals rely on planetaries and vertical augers. By keeping the design simple and robust, a Supreme Vertical Processor ensures that the end user will experience far less down time and maintenance requirements.

"What is the difference between a vertical processor and a horizontal mixer?"

The Supreme vertical processor is designed to have fewer wear points and a simplicity that gives hassle free maintenance. While other vertical and horizontal mixers may find ways to cut corners or reduce cost, Supreme focuses on quality and craftsmanship.

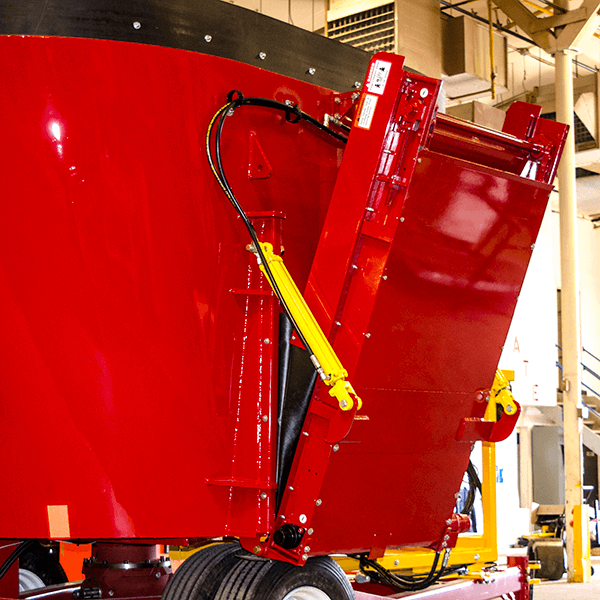

The tub is designed with sloped walls so feed will slide easily from the top to the floor. Because of the slope there is enough space between the edge of the auger flighting and the tub wall which creates a fast moving volcanic action. Supreme’s mixing tubs have been carefully designed for easier loading, better mixing and longer life. The unobstructed opening facilitates loading of whole bales, regardless of type or size. Thorough mixing is assured because there are no restrictions or dead spots that can hamper material flow in the cutting and mixing process. As a result, material won’t grind or tear apart against the sidewalls or in the corners, preserving the quality of your feed. Finally, by eliminating corners, pressure and wear-points on the machine are eliminated, greatly prolonging the life of the unit.

At the heart of a Supreme Processor is Supreme’s patented vertical auger design, which delivers incomparable performance with even the most difficult materials yet requires less horsepower to operate than other vertical mixers. You’ll be able to process all types, sizes and combinations of bales without the need to pre-shred, pre-process, or break up roughage prior to loading.

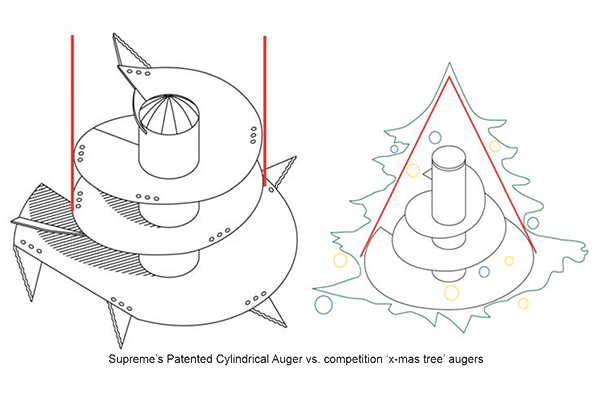

The free standing vertical auger features four patents that are instrumental in separating the performance of the Supreme from other vertical mixers. The uniform and wider flighting allows more feed to carry up through the center of the auger to the top. As the auger rotates, it moves feed from the center of the auger outward towards the walls, creating a volcanic effect. When an auger has a Christmas tree or tiered shape like competition mixers, the feed will fall off the flighting before it gets to the top and only the bottom half of the load will get mixed. This is very easy to identify, as there is usually no outward movement or volcanic effect.

If the auger flighting is too wide it will restrict the feed from falling down the sides of the tub, which in turn will slow down the mixing process and/or cause the feed to spill out over the top of the tub. The specially angled top cutting knife promotes the rapid breakdown of larger bales. The kicker plate directs material to the center of the auger. The cylindrical auger design efficiently moves all materials from the bottom of the tub to the top. The cutaway section on the auger allows feed to fall from the top to the bottom of the tub. These combined features are what produce the volcanic mixing action that quickly and gently blends all materials in the tub.